The Demag DH electric wire rope hoist was introduced to themarket in 1985 at the Hanover Fair. Since then, the model has served customerswith lifting needs up to 75 tons and in extreme environments. Like anyequipment used in your shop, proper maintenance and inspection is necessary tokeep you up and running to limit unnecessary downtime. One component on the DHwire rope hoist, and all wire rope hoists, that needs replaced periodically isthe rope guide. We are going to take you through how a trained servicetechnician would replace a broken or worn out rope guide and give you some tipson what prolongs the life of this component.

What does the ropeguide do on a wire rope hoist?

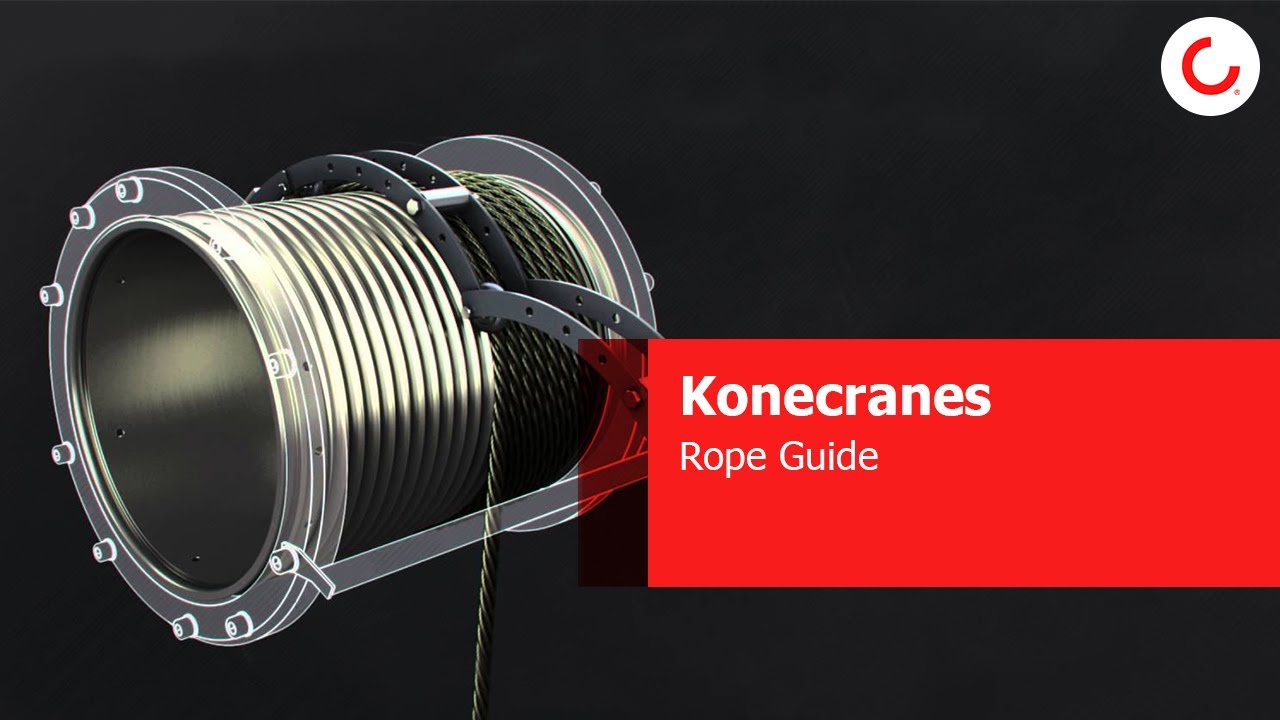

The function of the rope guide is to prevent the formationof loops in the wire rope while operating the hoist. The easiest way tovisualize this concept is with a failed cast on a fishing trip. Remember allthose tangles in your fishing line after a cast that wasn’t smooth? The ropeguide helps prevent that from happening. If a wire rope hoist were to formloops, it would be detrimental to the hoist unit itself. Trapped loops createslack in the wire rope so when the hook is lowered, the released slack resultsin shock-loading. Rolling over loops with consecutive wraps could result in asheared rope and a dropped load because the overlap presses the underlying wirerope against the sharp-edged drum grooves. Both situations are dangerous tocrane operators and your workforce in the area. Put safety first and rememberto inspect your wire rope hoist at recommended intervals and properly train allpersonnel.

Why does the ropeguide need replaced or adjusted?

View & download of more than 193 Terex PDF user manuals, service manuals, operating guides. Boom Lifts, Lifting Systems user manuals, operating guides & specifications. Title: Demag Manual Author: www.gardemypet.com-2020-12-03T00:00:00+00:01 Subject: Demag Manual Keywords: demag, manual Created Date: 12/3/2020 1:48:08 PM. That is why we developed the Demag DMR modular rope hoist. You can benefit from ground-breaking flexibility in all types of applications: from stationary installations to crane systems. For the first time, a rope hoist can be built either in a C-design or co-axial design utilising one basic technology.

Rope guides shipped with Demag DH hoists are made ofpoly-amide plastic. Modern rope guides are designed to include a doublepressure roller assembly where rollers press directly on the rope so it smoothlytracks into the drum groove. This results in positive and consistent spooling.Demag wire rope hoists, including the DH and DMR models, have been designed soinspection, adjustment and replacement is easily accessible. Like any otherwear part on equipment, as the rope guide plastic rides on the steel drum, theinside diameter (ID) wears over time. Once the operator or the inspector seesthe rope guide wobble during operation, it’s time to replace or adjust it.Another issue your inspection may find is a cracked rope guide. A cracked ropeguide can happen for a variety of reasons, but it’s frequently due to a loadbeing side pulled.

What is the processto adjust or replace a rope guide on the DH wire rope hoist?

The anatomy of a rope guide is simple. It has two majorsegments that overlap where they join. It has slotted holes for simple nut andbolt connections. Sometimes when you see a rope guide wobbling during use,adjusting it can fix the issue. Unfortunately, there is only so much adjustmentthat can be made until replacement is necessary. For a trained technician,adjusting the rope guide is simple. They loosen the bolts, bring the two halvescloser together and retighten the bolts so the guide can still move freely withoutbinding on the outside diameter of the drum.

As always, adjustment or replacement of a wire rope guideshould always be done by a qualified technician. Whether adjusting orreplacing, the first step is to release the pressure exerted by the rollers.This is accomplished by prying up on one half of the roller assembly to align aseries of holes across the two halves of the assembly for straight-on insertionof a pin or similar object. This pin holds back the rollers from exertingpressure and the guide can be removed. When you are installing a new ropeguide, a pin is already inserted in this hole. Whether you are adjusting orreplacing it, remember to remove the pin when finished with installation on thedrum so the rollers can exert the pressure needed to do their job.

How can I extend thelife of a rope guide?

There are many factors that determine the life of a ropeguide. Since the part is made of plastic, they are more vulnerable to theeffects of a side pull. This brings the steel wire rope in contact with theplastic guide, which can cause the guide to crack or inflict other damage. Sidepulling while lifting a load should be avoided. Always make sure your craneoperators have proper training. Another tip to extend life is regarding thetorque arm. The torque arm rides on a portion of the hoist frame. Keeping thisarea as clean as possible will prevent binding and subsequent breakage of thetorque arm. If you do follow these two suggestions, but still find that you’rereplacing the rope guide often, Demag offers reinforced rope guides made from acombination of plastic parts with metal reinforcements. Contact your authorizedDemag dealer to order.

The rope guide is an important part on your DH wire ropehoist. It assures the wire rope is spooled properly on the drum so you can liftloads safely. Keeping spare parts on hand can help you minimize downtime and beprepared to get the job done. Remember proper inspection and maintenance arekey to catching issues early. Always call in a qualified technician for the jobbecause safety is always your #1 priority.

Demag has network of authorized dealer partners across the US and Canada to help you maintain your equipment or be there to support you when you need to order parts or components. Contact us today!

DEMAG WORKS 24/7 SO YOU CAN TOO

You work hard to meet your customers’ expectations, and we work hard to meet yours. We’re committed to your business success and know that when your cranes work, jobs get done and you make money. You can call our free support line anytime day or night, 24/7.

And we can even come to you, to get your crane back to work.

Looking for support as a Demag cranes owner? Many countries are serviced by a local distributor. Contact your local Demag distributor for parts, service and training support:

For factory direct support, please search for the correct contact below.

Australia

Brazil

0800 69 83739

Demag Overhead Crane Parts

North America

Demag Manual Trolley

+1 (833) My-Demag

customersupport@tadano.com